As a packaging OEM, we need to stay ahead of trends that affect the industry. In other words, our machinery needs to work seamlessly within those trends that catch fire.

One of those trends is retail-ready packaging (RRP), which is being driven by several big box stores. In its simplest form, Walmart defines RRP as easy to identify, easy to open, easy to replenish, easy to shop and easy to dispose of or return. They make it sound … well … easy. While the concept is easy to wrap your head around, the challenge for suppliers is a bit more complex.

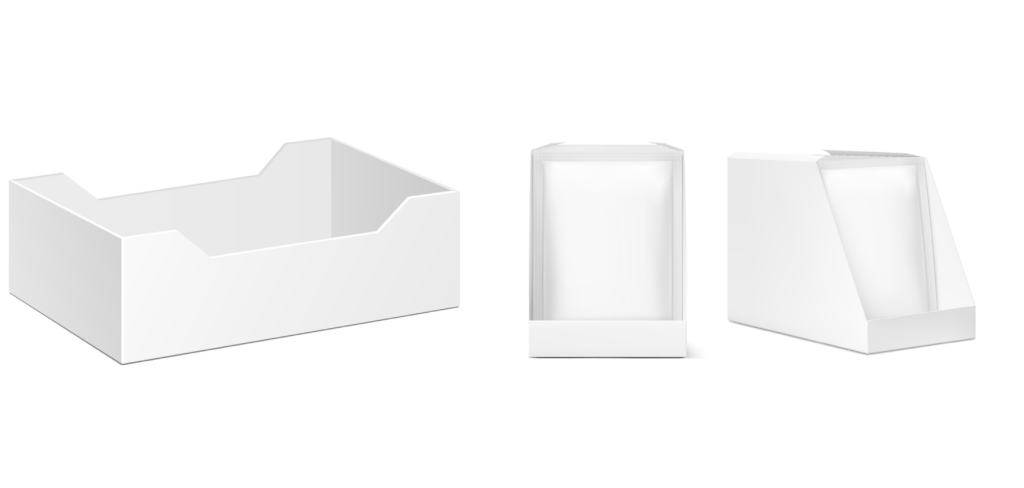

The idea behind RRP is to limit inventory back in the store’s warehouse. As inventory arrives, it is opened and placed right on the shelf, with the packaging acting as the display. When the last product is sold, the packaging is discarded. This helps create operating efficiencies in the stores by limiting inventory, while also providing a more dynamic customer experience, through better, more informed packaging that touts features and benefits, and other product information.

RRP is leading to is a greater number of SKUs and case sizes. Instead of producing a standard 24-pack case, retailers are looking for smaller cases sizes; four-, six-, eight-, and 12-packs are becoming common fixtures on shelves. To meet those ever-changing packaging counts, flexibility in packaging machinery has become a must-have.

It was not that long ago that a mechanically based packaging machine was designed to run one format, and that was it. Today, with the advent of servos and different motion controls, machines can be programmed to run a variety of different formats. Customers are telling us they may need to run 12-packs in the morning, changeover to 24-packs in the evening and then run six-packs tomorrow. To do that successfully calls for packaging machinery to be flexible.

The onus has fallen on OEMs to stay abreast of trends affecting the packaging industry. These are the types of partners who are not only supplying you with the right solutions to be successful, but keeping an eye open on your behalf.

Doug Strong is the Northeast Regional Sales Manager for Brenton. He can be reached at doug.strong@promachbuilt.com; https://www.brentonengineering.com/