Ensure smooth pharma packaging line startup in a matter of weeks, not months.

In an ideal world, a new pharma end of line packaging system will run at peak output in a matter of weeks after set up, not months. The majority of documentation and training will be completed prior to installation for better overall operation. Internal staff time and travel costs for the acquisition of the new line will be minimized. In the case of pharmaceutical packaging, the time required for validation could be reduced by as much as 50 percent, by creating and populating the bulk of the Installation Qualification/Operation Qualification (IQ/OQ) documentation prior to the Factory Acceptance Test (FAT). These benefits of turnkey end of line integration are not reserved for an ideal world. They happen daily and the trend toward more successful startups through turnkey integration – delivering a pre-tested fully functioning end of line system rather than assembling the line and testing it at the customer’s plant – is gaining strength.

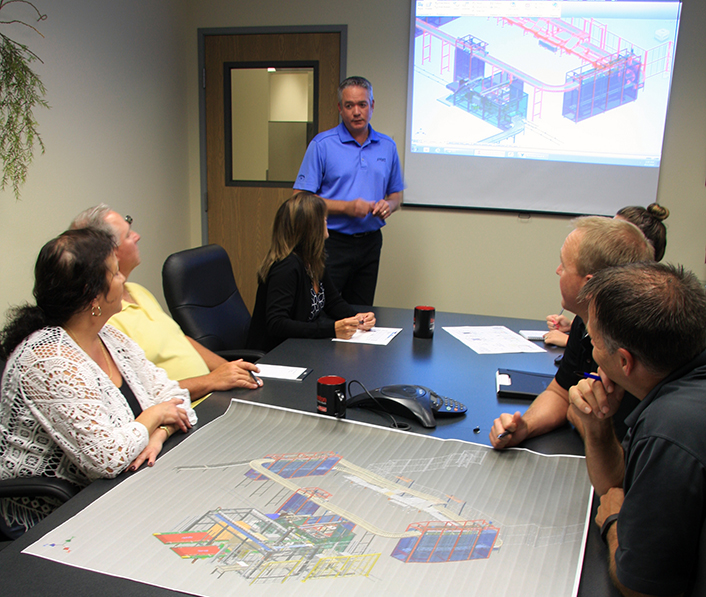

Recently, the end of line integration team at Brenton Engineering, a Pro Mach business, came together to identify the key factors for successful turnkey integration for pharma companies that support on time and on budget startup projects. Having a formal integration process and methodology was identified as a key to success. Controls expertise across various machines was also cited as essential.

As the discussion progressed, it became clear that developing an integration checklist – an operational secret sauce – or a top control technology staff were indeed important but did not serve to differentiate the adequate integrator from the stellar performer. In the end, the team identified six guidelines end users can follow for ensuring fast start up and all of the other benefits outlined above.

One dictionary definition of a guideline is a rope to aid in crossing over a difficult point. Similarly, the guidelines in this article are provided as aids in moving with confidence from concept to a performance driven end of packaging line system. When evaluating potential integrators and while moving through the process, end users should look for:

- An original equipment manufacturer (OEM) of cartoners, case packers, or palletizers that also specializes and is successful in turnkey integration.

- OEMs that understand the value of weekly communication during the project.

- OEMs that employ certified project managers or project managers on track for certification.

- OEMs that run productivity and safety risk assessments for every system on the line.

- OEMs that stage factory acceptance tests (FATs) that not only focus on running the line at specified rates, but also facilitate training.

- OEMs that understand the importance of IQ/OQ validation and that actively facilitate the development of the bulk of the documentation by the end of the FAT.

Guideline 1: Find an OEM of a core machine that has made a successful business in end of line integration

The leading suppliers today unquestionably have the latest in servo motion control technology for fast reliable changeover, superior diagnostics for quick identification of root cause issues, and first rate technical support, all of which contribute to high end overall equipment effectiveness (OEE) metrics. But system integrators, which are basically engineering and project management companies, can never match the OEM in terms of understanding the upstream and downstream inputs and outputs to the core machine that will serve to optimize the entire end of line. Because of this expert knowledge, some of these leading OEMs have built a thriving turnkey integration business. Another point in favor of working with a leading OEM versus the system integration company is that the OEM has a machine builder’s eye for good equipment. In some turnkey projects, the OEM is asked to select the other machines on the line. That OEM has every incentive to find the best, low risk solutions for upstream and downstream processing that complements its own machine.

Ask the OEM for references. Visit the plant to see turnkey systems being built. It will be clear from the physical set up – an orderly, well equipped, and expansive workspace – whether turnkey integration is a hobby or a profession for the OEM candidate. Ask what the team looks for when selecting upstream and downstream solutions. The answers will be illuminating.

Guideline 2: Work with an OEM that lives and breathes the value of communication

Without timely, accurate, and focused communication, a turnkey integration project will never live up to its potential because too many details will be missed and expectations go unfulfilled. The best way to evaluate a potential OEM/turnkey integrator is to ask what the OEM thinks are the top contributors to the success of a major project. If the answers never quite touch on the importance of frequent updates –verbal or written updates at least once a week by the project manager to the customer and other OEM suppliers – then the prospective integrator simply doesn’t get it. Conditions change quickly on these projects for the end users, OEM/integrator, and the other OEMs supplying machines. Without acknowledgement and fast response, small problems tend to be ignored until they are difficult ones. If the prospective OEM/integrator independently explains why its people emphasize communication and how they approach it, take note. These integrators are battle tested.

Guideline 3: The OEM/integrator that is serious about integration will have certified project managers or project managers in the process of earning a certification

Ask any successful project manager what is project management and he or she will say it is both an art and a science. The art involves people skills – leadership abilities, a high degree of understanding non-verbal communication, and an active interest in listening. The science comes from the project management’s vast body of knowledge acquired through more than a century’s worth of mammoth construction projects, product development and manufacturing, military procurement, systems deployment, and software engineering.

Anyone can buy project management software. That does not make him or her a project manager. The premier professional organization in the United States, the Project Management Institute (PMI), www.pmi.org, knows what it takes to be an effective project manager. PMI administers the Project Management Professional (PMP) certification, the gold standard for certifying project management expertise. In order to qualify to take the four-hour PMP certification exam, a candidate must first have a minimum of either 4,500 or 7,500 hours leading and directing projects. The difference is based on level of education – less experience for a candidate with a four-year degree, more required for a person with a two-year degree or high school diploma. Certification candidates must also have a minimum of 35 hours of project management education. All PMP certified project managers must accumulate 60 professional development units (PDUs) every three years to maintain their credential. Earning a PMP certification is an achievement. If the OEM is serious about making integration a core competency, then it hires PMPs or has PMP certification as a performance goal for members of its team. This ultimately means that every integration customer’s single point of contact during the project will be a professional well versed in both the art and science of project management.

Anyone can buy project management software. That does not make him or her a project manager. The premier professional organization in the United States, the Project Management Institute (PMI), www.pmi.org, knows what it takes to be an effective project manager. PMI administers the Project Management Professional (PMP) certification, the gold standard for certifying project management expertise. In order to qualify to take the four-hour PMP certification exam, a candidate must first have a minimum of either 4,500 or 7,500 hours leading and directing projects. The difference is based on level of education – less experience for a candidate with a four-year degree, more required for a person with a two-year degree or high school diploma. Certification candidates must also have a minimum of 35 hours of project management education. All PMP certified project managers must accumulate 60 professional development units (PDUs) every three years to maintain their credential. Earning a PMP certification is an achievement. If the OEM is serious about making integration a core competency, then it hires PMPs or has PMP certification as a performance goal for members of its team. This ultimately means that every integration customer’s single point of contact during the project will be a professional well versed in both the art and science of project management.

Guideline 4: Conducting performance and safety risk assessment is standard operating procedure for the OEM/integrator

The OEM/integrator of choice will as a standard practice examine every system on the line and evaluate meantime between failure and how that affects production rate. These risk assessments may lead the OEM/integrator to build in accumulation lanes to ensure the line keeps moving during short periods of downtime or take other preventative steps to ensure high OEE such as increasing human machine interface capabilities or installing vision systems at key points on a machine.

The OEM/integrator will also evaluate all the machines on the line for safe operation as defined by current industry standards. They will take steps to bring systems, even those that are not the core machine – up to those standards by adding guards, emergency shut offs, hold in place actuators, and more. Simply bolting on conveyors between machines and writing control code to ensure proper handshakes between PLCs is not enough today. Customers deserve better. Ask the prospective OEM/integrator about its approach to risk assessment. If the team on the other side of the table talks exclusively about its own core machine, then take that as a warning sign.

Guideline 5: The FAT should not only be about meeting the design specification, but also about fast startup and trained and confident operations personnel

One of the efficiencies offered by the turnkey project is that the customer does not have to travel to each supplier’s plant for individual acceptance tests. This is a major savings in time and cost. Furthermore, the turnkey FAT gives the customer the chance to evaluate the performance of the entire line, which is really much more valuable than machine by machine demonstrations in isolation. As stated earlier, well before the FAT, the prospective customer should tour the OEM/integrator’s plant and determine whether the facility has the space to build a core machine and assemble a new packaging line around it. Ascertain whether the OEM has sufficient room off the assembly floor for training during a FAT. Talk with the OEM’s training personnel. Are they experienced and enthusiastic? The FAT in effect is the launching pad for all elements of future productivity and performance. Determine whether the OEM/integrator shares this idea and has the resources to carry out the mission. It is absolutely essential that the prospective OEM/integrator explain the process for fast teardown and start up at the customer plant. The prospect must be able to describe how it approaches mechanical and electrical connections that enable ramp up to high OEE in a matter of weeks. That is where the biggest value of turnkey integration ultimately rests.

Guideline 6: Leave the FAT with IQ/OQ validation documentation prepared by the OEM team that built the key machine and integrated the end of line system.

OEMs that follow Food and Drug Administration Guidelines for 21 CFR Part 11 will have a wealth of detailed information on the system’s inputs and outputs. Preparing IQ/OQ may require four weeks for the OEM. However, this four-week effort is roughly half of the eight weeks a pharma company typically invests the same work. The OEM knows the system’s software. Having the bulk or all of the documentation completed by the end of the FAT not only saves time for the pharma company, but also frees the customer to focus on faster, more trouble free startup. It says a lot about a turnkey OEM that prepares IQ/OQ documentation and does not push it off onto the customers. That OEM focuses on the fast and successful startup of the end of line system.