There is growing interest in consolidating palletizing/stretch wrapping operations closer to the shipping dock or warehouse facility in order to free up space for additional packaging capacity. Running multiple conveyors to a single palletizer/stretch wrapping operation not only adds valuable real estate for expanding packaging operations, but also offers these advantages:

- Minimizes the number of palletizers/stretch wrappers at the plant thereby decreasing capital costs and maintenance and labor

- Lowers handling time associated with moving pallets

- Keeps the packaging room cleaner by reducing the dust associated with shipping cases and fork trucks

- Improves safety by removing fork trucks from areas of high foot traffic

There are two solutions for multiple infeed palletizing, robotic cells and conventional palletizers.

Robotic cells

Robotic palletizers can accommodate multiple infeed lines – two to five lines per robot on average – and either single or multiple discharge lanes. The robots’ claims to fame are their flexibility and quick changeover. Depending on its end-of-arm tooling, a robot can handle various types of shipping containers – RSC, HSC, bags, and more. Robots are re-deployable and reprogrammable for use in other areas of the plant. Robotic palletizers are also scalable; as more infeed conveyors are added additional robotic cells can be cost effectively and efficiently installed. Robotic palletizers do not require accumulation conveyors, which is a large cost savings. In many applications the robotic palletizer has a smaller footprint than a conventional palletizer.

Conventional palletizers

High level, high speed palletizers are notable for their speed and volume capacity. These are large, rugged automated systems capable of forming pack patterns and laying down seven or more pallet layers per minute. These workhorses can handle up to 10 infeed lines. Accumulation conveyors are required for each infeed line to a conventional palletizer, adding cost to the system and expanding the footprint required. A rule of thumb is that each infeed line needs to accumulate a minimum number of cases equivalent to one and a half pallet loads.

Conventional high level palletizers come in multiple configurations in order to accommodate a wide variety of plant layouts. Control systems store multiple pack patterns and enable rapid automatic changeover. In state-of-the-art machines, touch screen pack pattern programming saves time and makes the operation of the equipment more efficient. Footprint is typically larger than the robotic palletizer. Advanced servo technology identifies problems with pack patterns more quickly than ever before and, like robots, remote diagnostics and tech support help create greater uptime.

Unfortunately, there is no rule of thumb for when to apply a robotic cell or a conventional palletizer

It would be wonderful to be able to say definitively that lower volume multiple infeed systems always do best with robotic systems and heavier volume multiple lanes are ideal for conventional palletizers. It is not that simple. There are a wide number of factors that impact which system is best for the operation. These variables include:

- Cases per minute

- Number of SKUs

- Pack patterns required

- Case sizes

- Type of shipping material

- Number of infeed lines

- Footprint

- Future plans for the operation in terms of new products and expansion potential

- Budget

- Return on investment (ROI)

For example, a customer came to Currie by Brenton with plans to run eight different infeed lines a single palletizing area. Based on the generalization that one robot is best for two to five lanes and the conventional palletizer best for three to ten lanes, the obvious answer would be to specify the conventional palletizer.

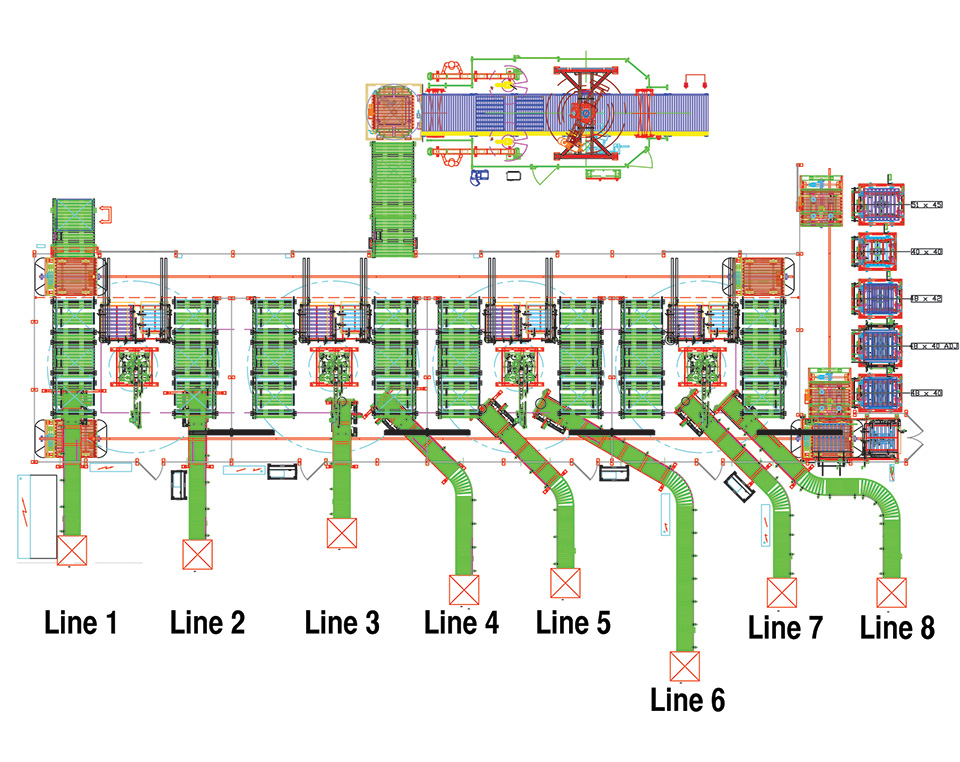

However, based on the cases per minute, number of SKUs, pack patterns, budget, lack of room for accumulation conveyors, and a number of other factors, the Currie by Brenton applications engineering team determined that the optimum investment for this customer would be four robotic cells, each of which would handle two lines. See Figure 1 for a schematic of the actual four stations being staged at the factory acceptance tests.

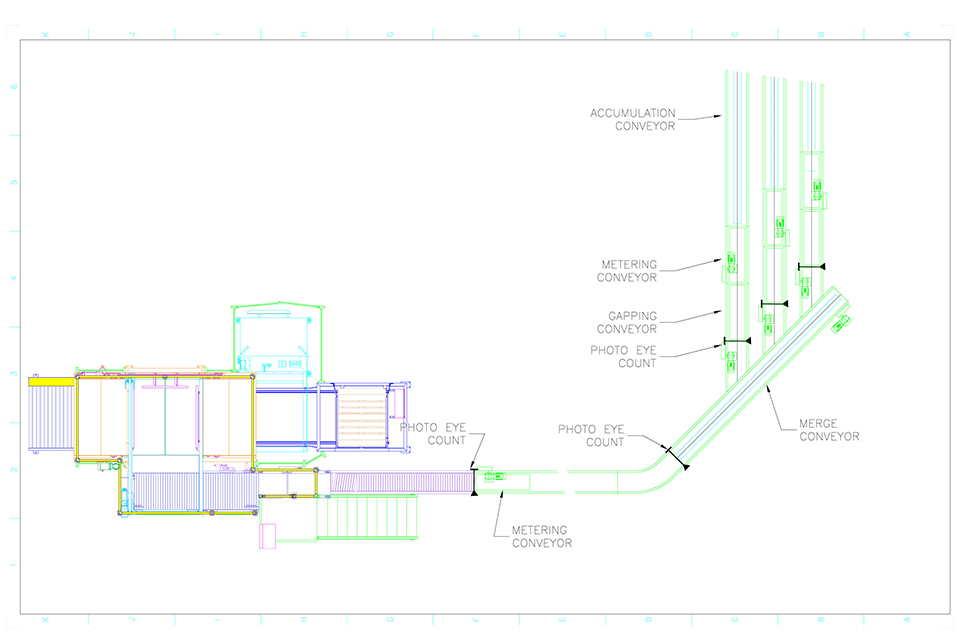

A second customer came to the applications team with the desire to consolidate three lines into one palletizer. A candidate for a robot cell? Turns out a conventional palletizer was the best solution based on budget, ROI, volume, and pack pattern. See Figure 2 for the final schematic.

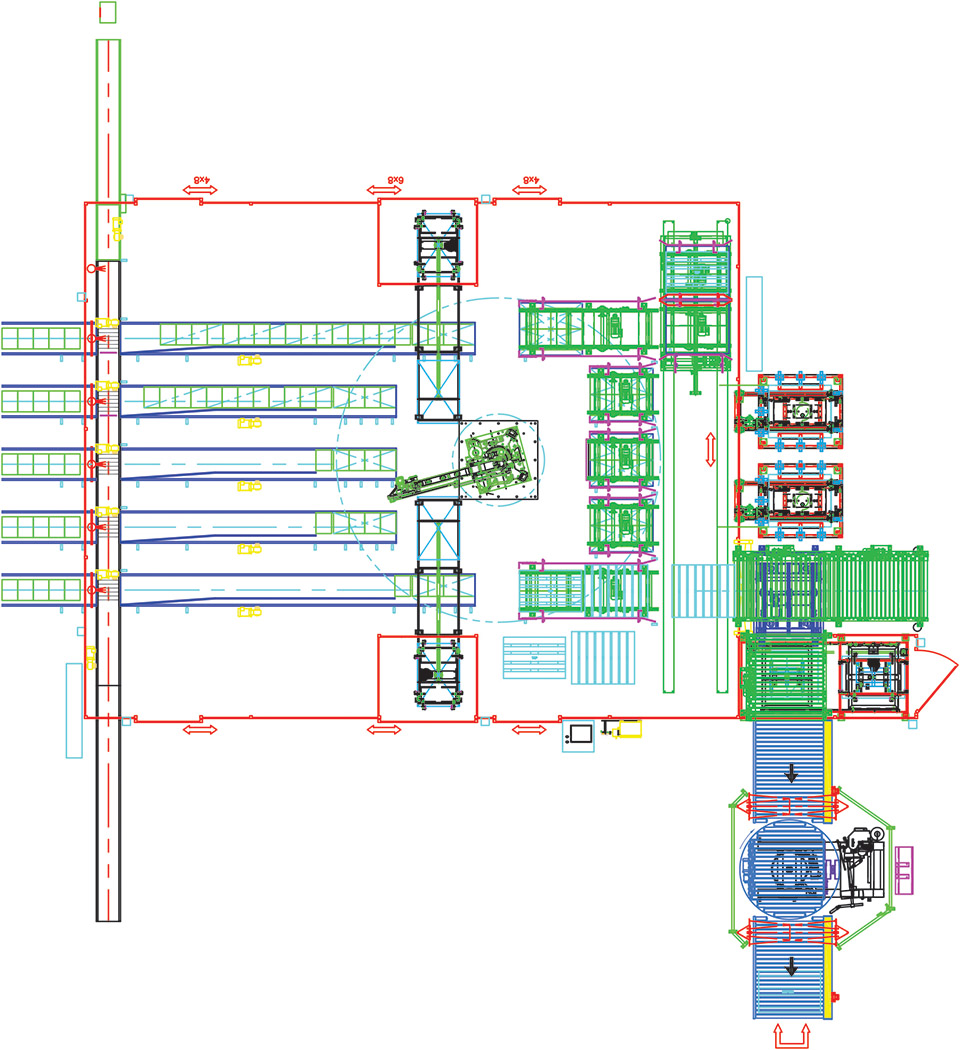

And lastly, another customer wanted a system for five multiple lines. Could the solution be two robots or perhaps one high level palletizer? No. Volume and pack pattern were such that this customer came away with a highly cost effective one robot system. See Figure 3 for a line drawing. These examples demonstrate that there is no easy approximation for identifying the best system. Each application must be examined on its own merits and a unique determination made.

When moving lines to a central area, it is best to work with an original equipment manufacturer (OEM) with expertise in both high level high speed palletizers and robotic palletizing cells. The dual system OEM will be neutral in finding the best solution, while the single system OEM can only respond with its solution, not necessarily the best solution.

The new solution has to be an integrated one – conveyors, palletizer, and stretch wrapper all tied together. Either a system integrator will put it together or the palletizer OEM will be the integrator and stage the factory acceptance test. There is a case to be made for the OEM as integrator. The reason is that the palletizer – either robotic or traditional – is the anchor device. To work effectively, the conveyors must infeed and discharge perfectly with the whole system streamlined for communication handshakes between units upstream and downstream of the palletizer. No one knows how to efficiently operate the palletizer and maintain the proper flow as well as the OEM. This is a powerful rationale for the OEM to integrate the system.

When discussing the project with the OEM determine whether the technical and project management teams have a track record of success. Definitely tour the factory acceptance test area at the OEM’s facility. Is it off in an unused corner of the building or does the OEM have a properly outfitted and spacious staging area for the factory acceptance test? It will become apparent quickly whether the OEM is right for the job of supplier and integrator.

The main point to remember is that the necessary technology exists for a central palletizing area to be successful, but it requires application expertise and robotic or conventional palletizing options in order to obtain the optimum solution.