Plants want more versatility in their packaging process, and flexible, intelligent EOAT is one way to get it. EOAT stands for end-of-arm tooling and it refers to a variety of options, from servo grippers and hybrid tooling to advanced tool changeover that are available to robot users.

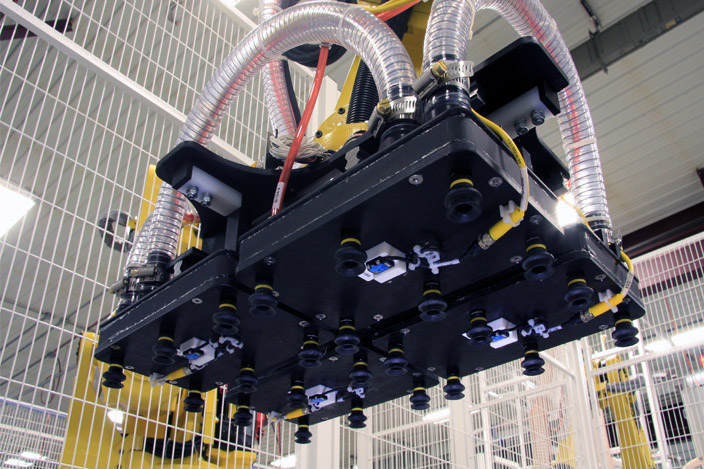

When creating a robotic packaging line to handle lunchmeat, cookies, cereal, flour, detergent, deodorant, 100 lb. bags, etc., engineers need to give the robotic End-Of-Arm-Tooling (EOAT) good thought since robots are not of much use without appropriate grippers or end effectors. The EOAT a major part of planning a functional robotic cell since the robot is only as good as the design of the tool that is attached to the end of the arm. A well-designed EOAT can be utilized to accommodate various sized product without manual adjustment and pack and/or palletizer multiple lines at the same time. One robot. One EOAT.

Additionally, the environment the EOAT will be used presents a design consideration. In raw food processing areas, end effectors are likely to be engineered with full stainless steel components that are guarded to prevent contaminants dropping off or under the tool into the raw food. Conversely, packaged products most likely will not need the full sanitary design.

Brenton custom designs end-of-arm-tools to accommodate each customer’s unique product and project application. Contact us for examples or to start a conversation about how we might help you with your application’s needs.