Case Packer Effectiveness

What does it mean for a piece of machinery to be effective? Effectiveness is the comparison of intended production rates to actual production rates – a time based evaluation. This is a simple calculation that produces a simple response; which raises the question if my effectiveness ratio is not 100% where do I start making improvements?

That is where OEE comes into play. OEE (Overall Equipment Effectiveness) provides an all-encompassing picture of machinery performance and directs you to determining where your losses are coming from. When calculating OEE you receive an objective set of data which will lead your operations team down the path to overall improved production. We are going to take a look the three components of OEE in light of case packing and suggestions for improving machine effectiveness, whether you be using a side load or top load case packer.

Availability

Availability is the time that a machine is up and running. This ratio compares ideal run time to actual run time.

Your facility operates in 8-hour shifts. What we don’t know is how many of those 8 hours does the machine actually run. During a shift, employees receive 2-15-minute breaks and 1-30-minute lunch. There are 80 minutes of changeover and 60 minutes of downtime throughout the day. All in all, of the 480 shift minutes the case packer is only running 280 – that is a loss of 200 minutes. The availability ratio is 58.3%.

Performance

Performance the evaluation of throughput, if the number of cases per minute is meeting your ideal rate.

The case packer runs 35 cases per minute at 280 minutes of actual run time yielding 9,800 cases, this is demonstrating ideal performance. If the packer began running at a reduced speed, say 25 cases per minute, you have now reduced the performance of the machine to 71.4% or a loss of an additional 80 minutes.

Quality

The evaluation of quality stems from how many cases were constructed according to spec. Did you have to reject any cases because they were damaged, incorrect pattern or weight?

Based on performance you are packing 7,000 cases per shift but you have 250 that are completed out of spec yielding a total of 6,750. Your quality ratio is 96.4%.

The results are in and this case packer demonstrated an OEE of 40%. This ratio is achieved by comparing time not running (availability = 58.3%), time lost by running at a slower rate (performance = 71.4%) and time lost by producing unapproved cases (quality = 96.4%).

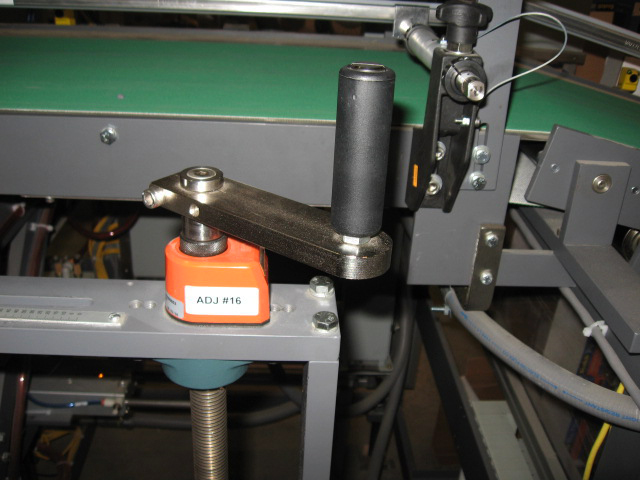

Brenton has proven that Strategic planning and prevention are the greatly help improve your OEE. The first way to improve machine availability is to reduce changeover time. Brenton takes this challenge head on with the implementation of tool-less changeover wherever possible, color coding the changeover parts, Siko Counters with hand cranks, and keyholing parts with a self-aligning Kipp handle. Full automation change over run through the HMI is also available. When running a robotic case packing application, this fully automatic changeover is demonstrated through robotic automatic tool changing. The robot is programed to release the end of arm tool (EOAT) onto a rack and pick up the next.

Downtime is another piece of the availability puzzle. Scheduling preventative maintenance and tracking downtime on your HMI are essential steps for the reduction of downtime. Brenton supports its equipment with a complete Aftermarket parts, service and retrofit team. Our parts team can help you keep common wear items on hand so you are ready for scheduled maintenance and unplanned repairs. Another aspect of preventative equipment care are machine audits. These audits include safety reviews, machine analysis, visual inspections and adjustments.

The next phase of improving OEE is performance. Improve the performance of your equipment by stabilizing the speed. Ensure that your conventional equipment is designed to a 10% overspeed rate so that you are never maxing it out. Robotic case packers should not be designed with more than 86% utilization without close engineering review. That 14% buffer provides support for the system. If you are looking for more speed, contact our Retrofit department. They have solutions available for Brenton and non-Brenton equipment to keep you running at the pace you require.

Speed is important up and down the line from your case packer. ProMach Performance Services surpasses the competition in line data, analysis, improvement, modeling and testing! If you are looking for performance this is your team.

Finally, there is quality. When your case packer is damaging cases, you are losing out on more than just time, material resources are being wasted as well. To ensure that our case packers are gentle on your corrugate, Brenton uses top squaring fingers and bottom squaring flights. These capture the case at the top and bottom BEFORE compression is applied to ensure sides and flaps are not over extended or bunched during sealing.

The closer you get your OEE to 100% the smoother your line will run, most facilities aim for 85% OEE. Take the time to evaluate your case packer’s availability, performance and quality; your bottom line will thank you!

For more information about Brenton case packers please visit www.BrentonEngineering.com.