Brenton’s story began 29 years ago when a team of RAM Center (current Brenton) employees developed a custom code for their tire painter application that would put them on the map. This solution featured a multi-axis articulated robot controlled by a third party robotic control pendent. The pendent was then integrated into the HMI. The customer could interface with the robot through the HMI but all motion control was managed through the pendent. Since then, robots and robot controllers have evolved dramatically. With technological advancements always on the horizon, a team of Brenton robotics engineers decided it was time for the tire painting application to get a facelift.

An all PLC based program

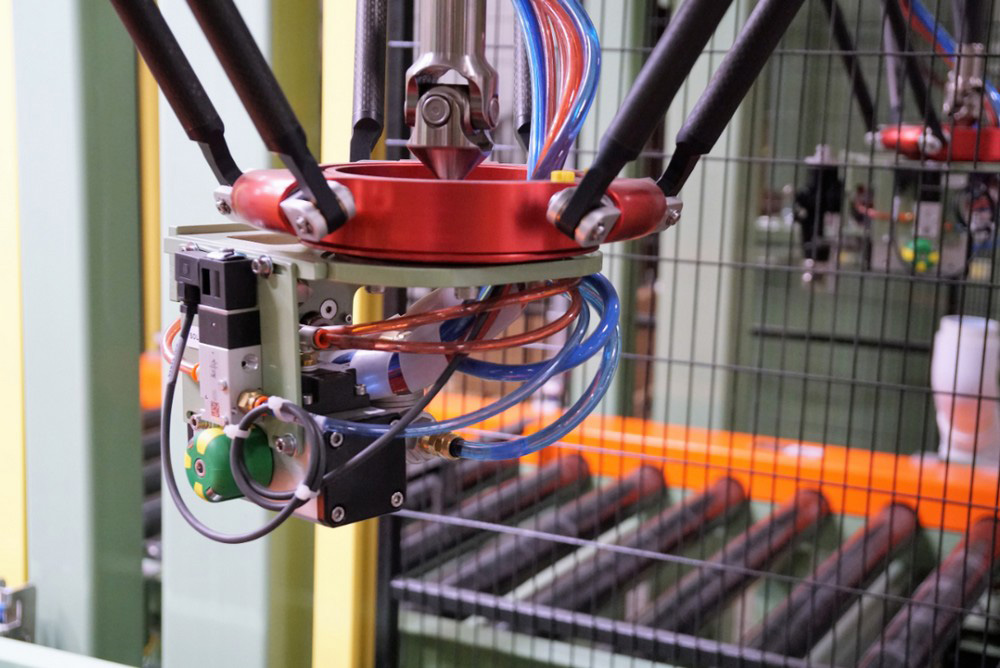

Brenton began engineering the NEW robotic tire painter. Featuring a 4 axis, delta style robot, this new solution is free of the dedicated robot controller hardware, utilizing the Allen-Bradley PLC to directly control the robot motion with PLC ladder logic. All robotic interfacing and movement is direct from the logic controls system – no more umbilical cord to pendent required! As a universally accepted platform, AB Rockwell seamlessly integrates with packaging lines. This allows for one program and one interface. This is monumental in the world of robotics.

Ready, set, go

In late 2017, Brenton began working with a US-based tire manufacturing company, and the solution was brought to life. Featuring two, simultaneous lanes, the Brenton application begins when tires are indexed into the painting system, one tire at a time. The tires are held at a pre-paint staging location until the system is ready. When the robot paint position is clear, the unpainted tire is indexed into position and the tire is painted by the robot or passed through if a black wall is detected and painting is not required.

Machine vision cameras locate the center of the tire and any decorative whitewalls or lettering that needs to be painted and sensors determine the height for automatic spray adjustments. These coordinates are passed to the PLC program which, in turn, develops the desired parameters and spray path. The robot only paints the decorative area of the tire. After painting a customer-defined number of the tires, the robot guides the spray gun and nozzle assembly through an automatic cleaning cycle and recharges with paint to resume automatic painting.

This new 2-lane system offers approximately a 25% increase in throughput over Brenton’s previous solutions and occupies nearly the same footprint for easy replacement of legacy installations. Interested in a new Tire Painter? Request a quote today!